Soldering Station Transformer DIY: A Comprehensive Guide

=====================================================

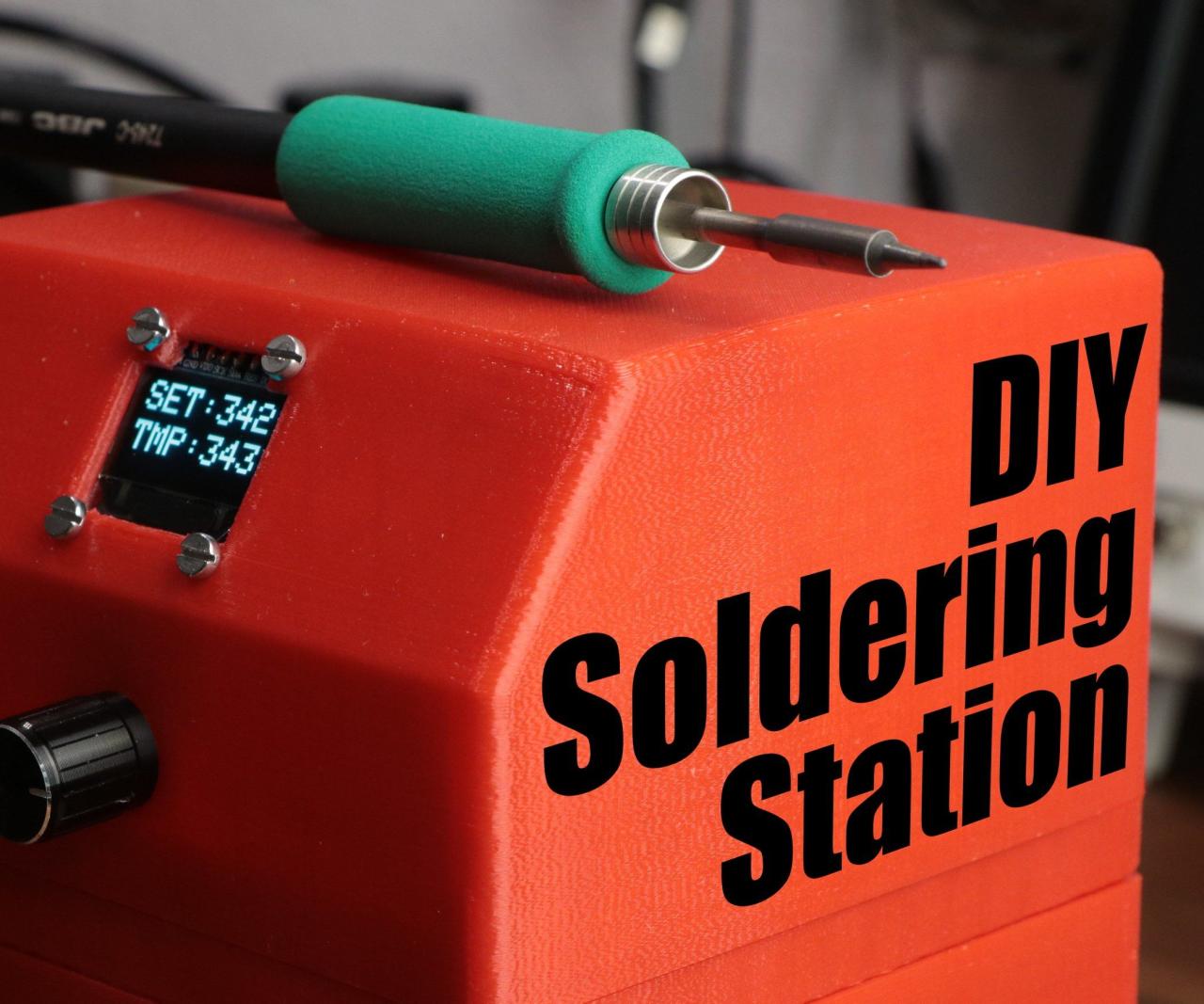

Hey there, fellow DIY enthusiasts and electronics hobbyists. Are you tired of using low-quality soldering irons that just can’t get the job done? Look no further. In this article, we’ll walk you through the process of creating your own Soldering Station Transformer DIY. That’s right, you’ll be making your very own high-quality soldering station without breaking the bank.

What is a Soldering Station Transformer DIY?

Before we dive in, let’s talk about what a soldering station is. A soldering station is a device that controls the temperature of a soldering iron. It’s essentially a power supply that provides a stable voltage to the soldering iron, allowing you to work on your projects with precision and accuracy. A Soldering Station Transformer DIY takes it a step further by creating a custom transformer that powers the soldering station.

Why Build a Soldering Station Transformer DIY?

There are several reasons why you might want to build a Soldering Station Transformer DIY. First and foremost, it’s a cost-effective solution. Buying a commercial soldering station can be expensive, especially if you’re on a tight budget. By building your own, you can save money and still get high-quality results. Additionally, building a Soldering Station Transformer DIY allows you to customize the design and features to your specific needs. Whether you’re working on small electronics projects or large-scale industrial applications, you can create a soldering station that meets your requirements.

Benefits of a Custom Soldering Station Transformer DIY

So, what are the benefits of building a custom Soldering Station Transformer DIY? For one, you’ll have complete control over the design and features. You can choose the type of transformer, the voltage and current output, and even add additional features like temperature control and digital displays. This means you can tailor your soldering station to your specific needs and preferences.

Another benefit is the cost savings. As mentioned earlier, buying a commercial soldering station can be expensive. By building your own, you can save money on the initial purchase and even on replacement parts. Plus, since you built it yourself, you’ll have the knowledge and skills to repair and maintain it.

Finally, building a Soldering Station Transformer DIY is a great learning experience. You’ll gain hands-on experience with electronics and transformer design, which can be applied to other projects and applications.

Materials Needed for a Soldering Station Transformer DIY

Before we start building, let’s take a look at the materials you’ll need. Keep in mind that this list may vary depending on your specific design and requirements.

- Transformer (e.g., EI-48, EI-66, or EI-104)

- Insulated copper wire (e.g., 20 AWG or 22 AWG)

- Ferrite core

- Wire wrap or solder

- Electrical tape or heat shrink tubing

- AC power cord

- Fuse or circuit breaker

- Voltage and current meters (optional)

- Digital display or temperature controller (optional)

Choosing the Right Transformer for Your Soldering Station Transformer DIY

The transformer is the heart of your Soldering Station Transformer DIY. It converts AC power from the mains to a stable DC voltage that powers your soldering iron. When choosing a transformer, you’ll need to consider several factors, including:

- Input voltage: This is the voltage from the mains that will be converted to DC.

- Output voltage: This is the voltage that will be provided to the soldering iron.

- Output current: This is the maximum current that the transformer can handle.

- Frequency: This is the frequency of the AC power (e.g., 50Hz or 60Hz).

Some popular transformer options for Soldering Station Transformer DIY include the EI-48, EI-66, and EI-104. These transformers offer a good balance between size, weight, and performance.

Step-by-Step Instructions for Building a Soldering Station Transformer DIY

Now that we have our materials, let’s start building. Here’s a step-by-step guide to creating a Soldering Station Transformer DIY:

Step 1: Design Your Transformer

The first step is to design your transformer. You’ll need to determine the input and output voltages, output current, and frequency. You can use online calculators or consult with an electronics expert to ensure your design is correct.

Step 2: Wind the Transformer

Once you have your design, you’ll need to wind the transformer. This involves wrapping insulated copper wire around the ferrite core. Make sure to follow proper safety precautions when working with electrical components.

Step 3: Add a Fuse or Circuit Breaker

To protect your Soldering Station Transformer DIY and prevent electrical shock, you’ll need to add a fuse or circuit breaker. This will ensure that the transformer shuts off in case of an overload or short circuit.

Step 4: Connect the AC Power Cord

Next, connect the AC power cord to the transformer. Make sure to follow proper safety precautions and use electrical tape or heat shrink tubing to secure the connections.

Step 5: Add Voltage and Current Meters (Optional)

If you want to monitor the voltage and current output of your soldering station, you can add meters or a digital display. This will help you fine-tune the performance and ensure that your soldering iron is operating within the correct temperature range.

Step 6: Add a Digital Display or Temperature Controller (Optional)

Finally, you can add a digital display or temperature controller to your Soldering Station Transformer DIY. This will allow you to set specific temperature ranges and monitoring parameters, giving you even more control over your soldering station.

Tips and Tricks for Building a Soldering Station Transformer DIY

Here are some additional tips and tricks to keep in mind when building your Soldering Station Transformer DIY:

- Use proper safety precautions when working with electrical components.

- Ensure that your transformer is designed for the correct voltage and current output.

- Use high-quality materials and construction techniques to ensure reliability and durability.

- Test your soldering station thoroughly before using it on a project.

Conclusion

Building a Soldering Station Transformer DIY is a fun and rewarding project that can save you money and provide you with a high-quality soldering station. By following these steps and tips, you can create a custom transformer that meets your specific needs and requirements. Whether you’re a seasoned DIY enthusiast or just starting out, this project is a great way to learn new skills and expand your knowledge of electronics and transformer design. So, go ahead and give it a try – you won’t be disappointed.

Why You Should Build a Soldering Station Transformer DIY

So, why should you build a Soldering Station Transformer DIY? For one, it’s a cost-effective solution that can save you money in the long run. Two, it allows you to customize the design and features to your specific needs. Three, you’ll gain hands-on experience with electronics and transformer design. And four, you’ll have complete control over the performance and reliability of your soldering station.

Take Your Soldering Station Transformer DIY to the Next Level

If you want to take your Soldering Station Transformer DIY to the next level, you can consider adding additional features like temperature control, digital displays, or even a soldering iron holder. You can also experiment with different transformer designs and materials to optimize performance and efficiency.

Final Thoughts on Soldering Station Transformer DIY

In conclusion, building a Soldering Station Transformer DIY is a fun and rewarding project that can provide you with a high-quality soldering station. By following these steps and tips, you can create a custom transformer that meets your specific needs and requirements. Whether you’re a seasoned DIY enthusiast or just starting out, this project is a great way to learn new skills and expand your knowledge of electronics and transformer design.