How to Repair Short Circuit Crankshaft Position Sensor

===========================================================

Hey guys, welcome back to our DIY repair series. Today, we’re gonna tackle a crucial sensor that keeps your ride running smoothly – the crankshaft position sensor (CKP sensor). A short circuit in this sensor can cause all sorts of issues, from rough idling to stalling. But don’t worry, we’ve got you covered. In this article, we’ll walk you through the steps on how to repair short circuit crankshaft position sensor.

Understanding the Crankshaft Position Sensor

Before we dive into the repair, let’s take a quick look at what the CKP sensor does. The CKP sensor is responsible for monitoring the crankshaft’s rotation and sending this information to the engine control module (ECM). The ECM then uses this data to adjust fuel injection, ignition timing, and other engine parameters.

Symptoms of a Faulty CKP Sensor

A short circuit in the CKP sensor can cause a range of symptoms, including:

- Rough idling

- Stalling

- Difficulty starting the engine

- Poor engine performance

- Check Engine Light illumination

If you’re experiencing any of these symptoms, it’s possible that your CKP sensor has gone bad.

Diagnosing the Problem

Before we start the repair, let’s make sure we’ve got the right diagnosis. Here are the steps to diagnose a short circuit in the CKP sensor:

Step 1: Consult the Repair Manual

Consult your repair manual for specific instructions on how to diagnose a faulty CKP sensor. The manual will provide you with troubleshooting steps, wiring diagrams, and other essential information.

Step 2: Use a Multimeter

Use a multimeter to check the sensor’s resistance and voltage. Compare the readings to the manufacturer’s specifications to determine if the sensor is faulty.

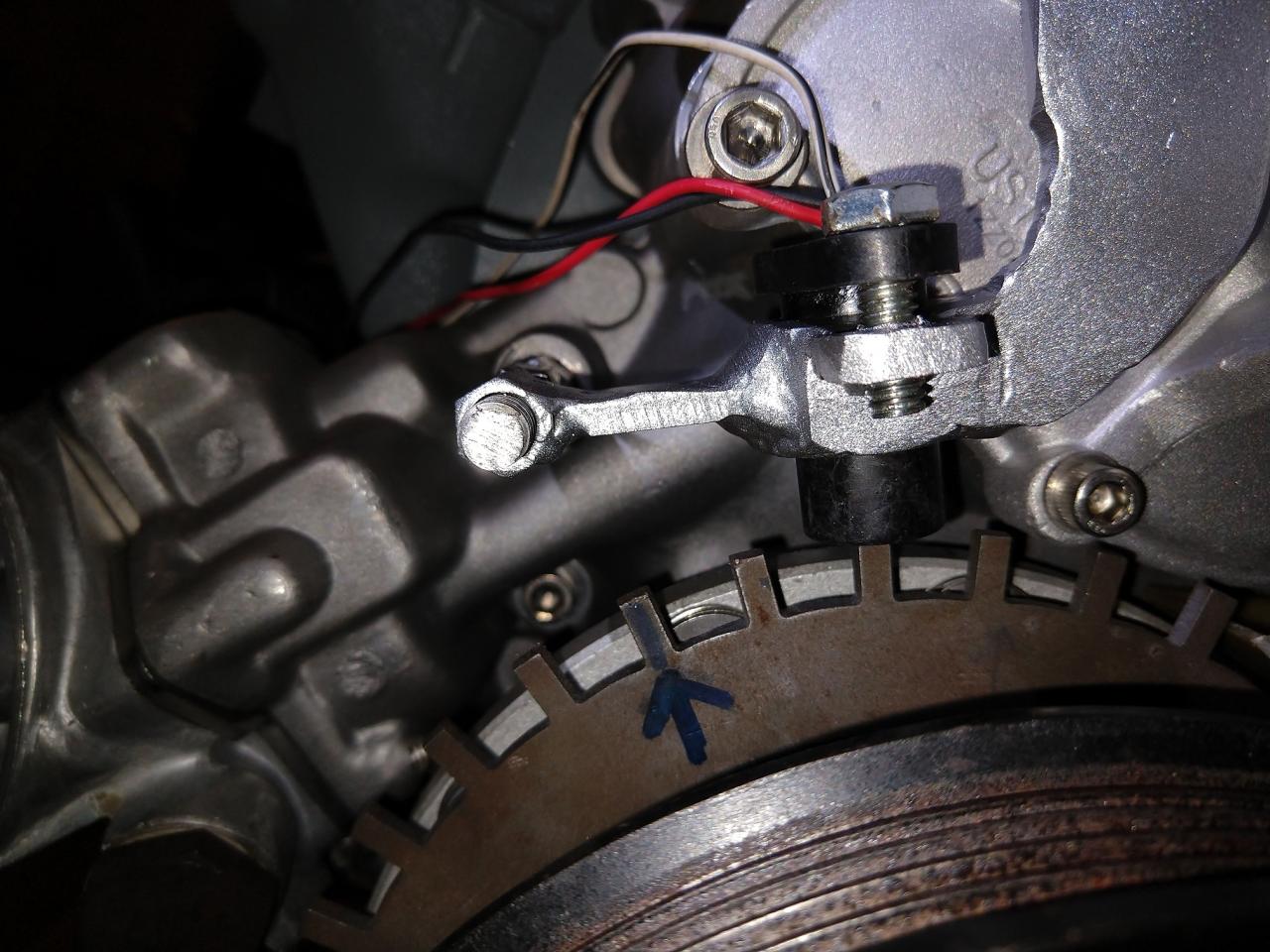

Step 3: Perform a Visual Inspection

Perform a visual inspection of the sensor, wiring, and connections. Look for signs of wear, corrosion, or damage.

How to Repair Short Circuit Crankshaft Position Sensor

Assuming you’ve diagnosed a short circuit in the CKP sensor, here are the steps to repair it:

Step 1: Purchase a Replacement Sensor

Purchase a replacement CKP sensor from a reputable supplier. Make sure the new sensor is compatible with your vehicle’s make and model.

Step 2: Disconnect the Battery

Disconnect the battery to prevent any accidental engine starts or electrical shocks.

Step 3: Remove the Old Sensor

Remove the old sensor and set it aside. Take note of the wiring and connections, as you’ll need to connect the new sensor in the same way.

Step 4: Inspect the Wiring and Connections

Inspect the wiring and connections for any signs of wear or damage. Replace any damaged wiring or connections as needed.

Step 5: Install the New Sensor

Install the new sensor and connect the wiring and connections as noted in step 3.

Step 6: Reconnect the Battery

Reconnect the battery and start the engine. Monitor the dashboard for any signs of trouble or issues.

Additional Tips and Tricks

Here are some additional tips and tricks to keep in mind when repairing a short circuit in the CKP sensor:

- Make sure to use a high-quality replacement sensor to avoid any future issues.

- Use a repair manual specific to your vehicle’s make and model to ensure accurate instructions.

- Take note of any other faulty components, such as wiring or connections, and address them as needed.

- Consider using a CKP sensor testing kit to verify the sensor’s functionality.

Conclusion

And there you have it – a step-by-step guide on how to repair short circuit crankshaft position sensor. Remember to take your time, follow the instructions carefully, and use the right tools to avoid any future issues. With the right knowledge and expertise, you can save yourself a lot of money and get back on the road in no time.

How to repair short circuit crankshaft position sensor is a relatively straightforward process, but it does require some technical knowledge and expertise. If you’re not comfortable with DIY repairs or if you’re unsure about any aspect of the process, consider consulting a professional mechanic for assistance.